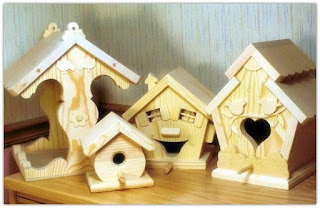

Simple Woodworking projects

His story, in his words ...

"Hit with the unmistakable smell of styrene and through the haze of a freshly sanded longboard I met with Rob Lion* to discuss my first custom board. Prior to this meeting I was admittedly, totally ignorant to the world of surfcraft and in visiting my board during the varying stages of it’s creation I was witness to Rob’s willingness to experiment with concepts, shapes and materials. The effect was instant and is why I almost immediately stripped the glass off an old board, eager to break the convention to which I was unconsciously adhering.

With more enthusiasm than method I hacked away at the unceremoniously stripped back surfboard. What ensued can only be described as a waste of what was a perfectly usable board. I decided making boards was a stupid idea.

Despite feeling disheartened at this failure I couldn’t quash my curiousity and I began to read around surfcraft and it’s construction. With my freshly gleaned knowledge I ordered my first real blank. This attempt was relatively successful and I started to build experiment after experiment, manifesting my on going research in tactile form.

As I continued to experiment, other like-minded surfers began asking for boards and soon I was receiving regular orders, refining my skills and processes with every board. Five years on I began to question the methods I was using, that smell of styrene and haze of sanding dust that had initially sparked excitement and intrigue were now an inconvenience to my adopted creative outlet.

Unhappy with the dust, noise and chemicals I was exposing myself to I stopped taking orders and began researching cleaner build methods. I had a fair idea of where I wanted to take my work and I began a new period of experimenting, focussed on a variation of the compsand method using external timber veneers.

I found this process to be much cleaner for myself, creating exponentially less dust, noise and smell with no compromise on what I can build. The resulting boards have a greater strength to weight ratio than those I used to build using the accepted standard of polyurethane foam and polystyrene resin.

Finally, limiting orders to 24 a year allows me continue doing what has got me this far, and enjoy the creative process. 24 is not a goal, it is a cut off point, a point at which I believe if exceeded the pressures of meeting demand would impact on the enjoyment I get and the quality of the boards I produce.

It is a privilege to explore the craft behind riding waves."

http://www.polymathsurfcraft.com

Simple Woodworking projects

0 komentar:

Posting Komentar